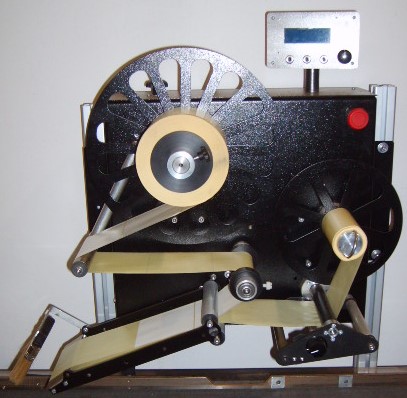

The CLA300 conveyor label applicator was designed to provide high speed, high volume labelling to the tops of containers or objects.

The CLA300 was designed to meet high speed and high volume automatic labelling requirements. It bolts onto an existing conveyor system, with an easy adjustment for the container height. With its large-diameter label roll, production is maximized.

The CLA300 caters for variations in the height of the container or other object being labelled. The minimum height of the object is set, and items of up to 50mm higher will pass through, and be labelled. Items in close proximity to each other can be labelled, provided that the sensor is set at a position where there is at least a 7mm gap between them.

Conveyor speed calibration is very easy. An object of known length is simply placed on the running conveyor belt when the applicator is in calibrate mode, and after passing in front of the sensor, the CLA300 is then correctly calibrated.

[table id=9 /]

The menu provides easy adjustment of the label position on the container, as well as a setting for the label length. The menu allows multiple profiles to be set up, so that numerical values do not need to be entered for the different parameters when changing products, simply choose a profile for the product to be labelled.

The backing sheet is rewound onto a separate reel after the labels are applied, with no core needed. When a new roll of labels is fitted, the old roll of backing sheet is easily removed and discarded.

The RW300 has been designed to work in conjunction with the CLA300, allowing large diameter rolls to be rewound, before being mounted on the CLA300 for application.